1. Brief History of LED

The basic knowledge that semiconductor materials can produce light has been understood as early as 50 years ago. In 1962, Nick Holonyak Jr. of General Electric Company successfully developed the first visible light-emitting diode that was used in practice. LED is the English abbreviation of light emitting diode. Its basic structure is a piece of electroluminescent semiconductor material, which is placed in a shelf with leads and then sealed with epoxy resin around it, that is The LED is solidly encapsulated, so the internal core wires can be protected, making the LED have good shock resistance.

Initially, LEDs were used as indicator light sources for instruments. Later, LEDs of various light colors were widely used in traffic lights and large-area display screens, producing good economic and social benefits. Take a 12-inch red traffic light as an example. In the United States, a long-life, low-efficiency 140-watt incandescent lamp is used as the light source, which produces 2,000 lumens of white light. After passing through the red filter, 90% of the light is lost, leaving only 200 lumens of red light. In the newly designed lamp, Lumileds uses 18 red LED light sources, which consume a total of 14 watts of power including circuit losses to produce the same light effect. Automotive signal lights are also an important area for LED light source applications.

2. LED headlight chip principle

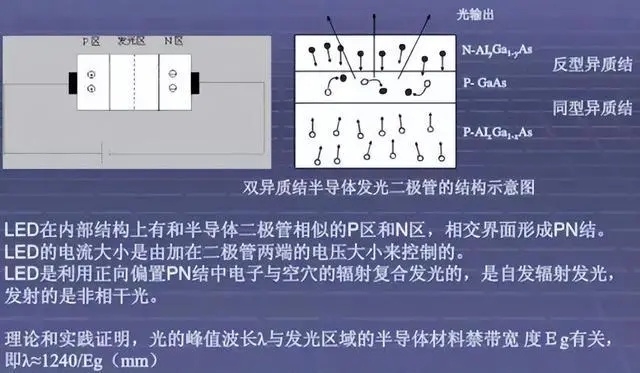

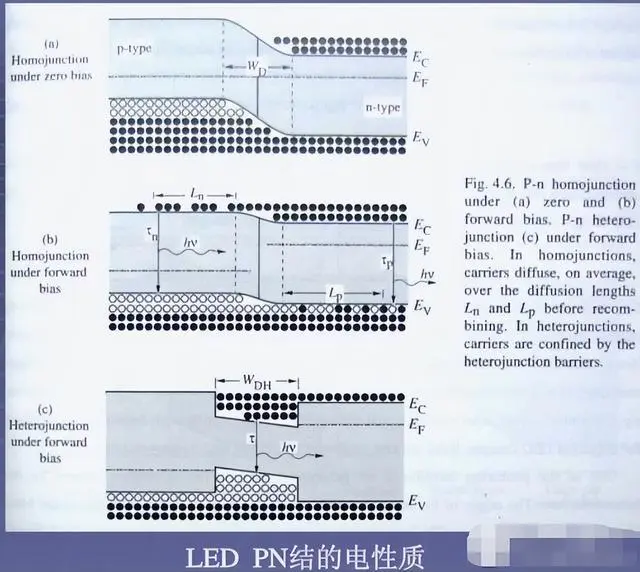

LED (Light Emitting Diode) is a solid-state semiconductor device that can directly convert electricity into light. The heart of the LED is a semiconductor chip. One end of the chip is attached to a bracket, one end is the negative electrode, and the other end is connected to the positive electrode of the power supply, so that the entire chip is encapsulated in epoxy resin. The semiconductor wafer is composed of two parts. One part is a P-type semiconductor, in which holes dominate, and the other end is an N-type semiconductor, where electrons are mainly present. But when two semiconductors are connected together, a "P-N junction" is produced. When the current acts on the wafer through the wire, the electrons are pushed to the P area. The electrons in the P area recombine with the holes, and then emit energy in the form of photons, which is the principle of LED light emitting. The wavelength of light, that is, the color of light, is determined by the material that makes up the P-N junction.

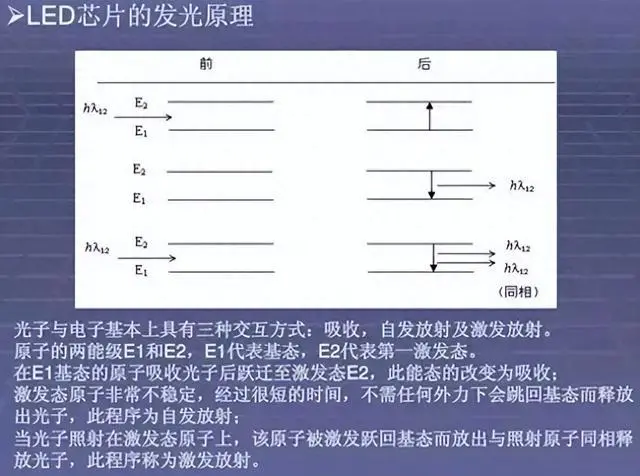

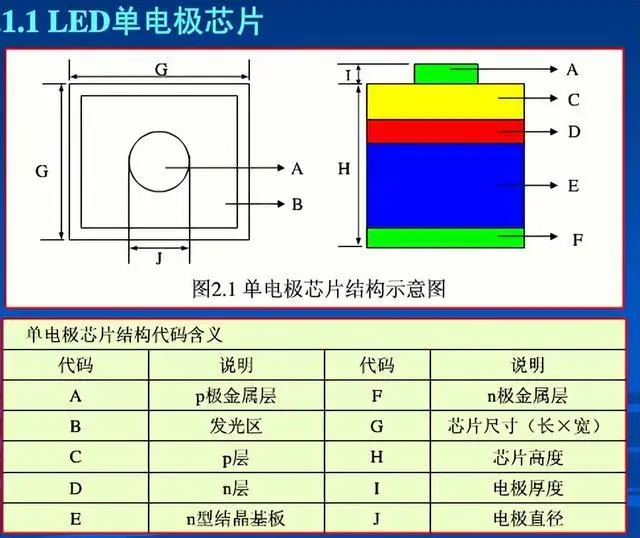

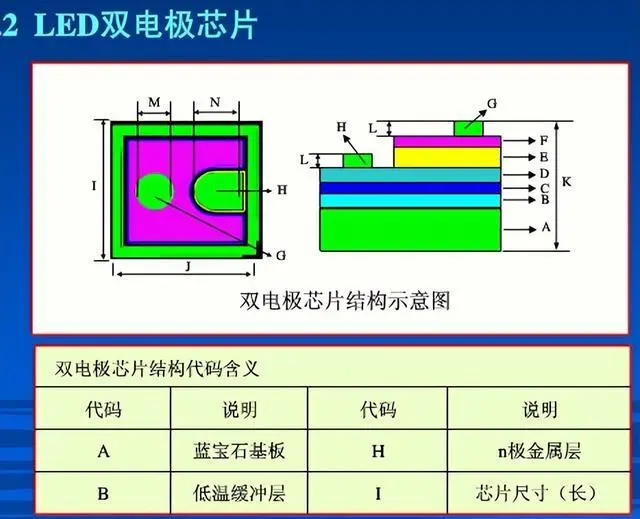

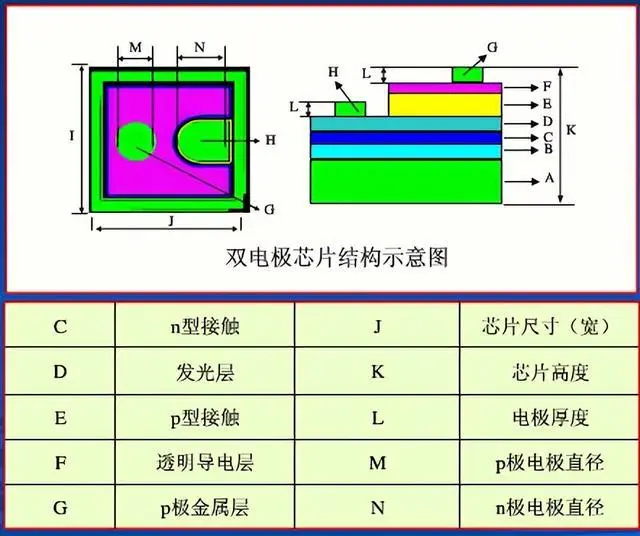

LED chip light emitting principle

LED chip internal structure diagram

3. Classification of LED chips

1. MB chip definition and characteristics

Definition: Metal Bonding chip; this chip is a patented product of UEC.

Features: (1) Using Si, a material with high heat dissipation coefficient, as the substrate, it is easy to dissipate heat. Thermal Conductivity; GaAs: 46W/m-K; GaP: 77W/m-K; Si: 125~150W/m-K; Cupper: 300~400W/m-k; SiC: 490W/m-K (2) Bonding (wafer bonding) epitaxial crystals through metal layers layer and substrate, while reflecting photons and avoiding absorption by the substrate. (3) The conductive Si substrate replaces the GaAs substrate, which has good thermal conductivity (the thermal conductivity is 3 to 4 times different) and is more suitable for high drive current fields. (4) The bottom metal reflective layer is conducive to brightness improvement and heat dissipation. (5) The size can be increased and used in high power fields, eg: 42mil MB.

2. GB chip definition and characteristics

Definition: Glue Bonding chip; this chip is a patented product of UEC.

Features: (1) The transparent sapphire substrate replaces the light-absorbing GaAs substrate, and its light output power is more than twice that of the traditional AS (Absorbable structure) chip. The sapphire substrate is similar to the GaP substrate of the TS chip. (2) The chip emits light from all sides and has an excellent pattern. (3) In terms of brightness, its overall brightness has exceeded the level of TS chips (8.6mil). (4) The dual-electrode structure is slightly worse than the TS single-electrode chip in terms of high current resistance.

3. TS chip definition and characteristics

Definition: transparent structure (transparent substrate) chip, which is a patented product of HP.

Features: (1) The chip manufacturing process is complex, much higher than that of AS LED. (2) Excellent reliability. (3) Transparent GaP substrate does not absorb light and has high brightness. (4) Widely used.

4. AS chip definition and characteristics

Definition: Absorbable structure (absorbent substrate) chip; through nearly forty years of development and efforts, the development, production and sales of this type of chip in Taiwan's LED optoelectronics industry are at a mature stage, and major companies are conducting research and development in this area. The level is basically the same, there is not much difference.

Mainland China's chip manufacturing industry started late, and its brightness and reliability are still far behind those of Taiwan's industry. The AS chip in this article specifically refers to the AS chip in UEC, eg: 712SOL-VR, 709SOL-VR, 712SYM-VR and 709SYM-VR.

Features: (1) Quaternary chip, prepared using MOVPE process, is brighter than conventional chips. (2) Excellent reliability. (3) Widely used.

4. LED chip material epitaxial types

1.LPE: Liquid Phase Epitaxy (liquid phase epitaxy) GaP/GaP

2.VPE: Vapor Phase Epitaxy (Vapor Phase Epitaxy) GaAsP/GaAs

3.MOVPE: Metal Organic Vapor Phase Epitaxy AlGaInP, GaN

4.SH: GaAlAs/GaAs Single Heterostructure (single heterostructure) GaAlAs/GaAs

5.DH: GaAlAs/GaAs Double Heterostructure (double heterostructure) GaAlAs/GaAs

6.DDH: GaAlAs/GaAlAs Double Heterostructure (double heterostructure) GaAlAs/GaAlAs

5. LED chip composition and light emission

1.Composition of LED chip:

It is mainly composed of several elements such as arsenic (AS), aluminum (AL), gallium (Ga), indium (IN), phosphorus (P), nitrogen (N), and strontium (Si).

2.Classification of LED chips:

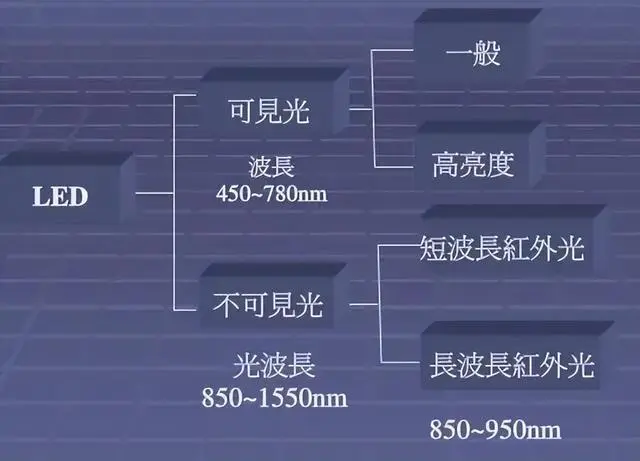

(1) According to luminous brightness:

A. General brightness: R, H, G, Y, E, etc.

B. High brightness: VG, VY, SR, etc.

C. Ultra-high brightness: UG, UY, UR, UYS, URF, UE, etc.

D. Invisible light (infrared): R, SIR, VIR, HIR

E. Infrared receiving tube: PT

F. Photoelectric tube: PD

(2) According to the constituent elements:

A. Binary wafer (phosphorus, gallium): H, G, etc.

B. Ternary wafer (phosphorus, gallium, arsenic): SR, HR, UR, etc.

C. Quaternary wafer (phosphorus, aluminum, gallium, indium): SRF, HRF, URF, VY, HY, UY, UYS, UE, HE, UG