The development of all things follows its natural laws. Halogen lamps are banned in the European Union, and LED headlights have also been pushed into a new wave. Even so, some car owners still think that halogen lamps are better. For example, at this time in the south, the rain god is inseparable. Some car owners still like halogen lamps because halogen lamps have strong penetrating power, which is one of the few advantages of halogen lamps. Even so, it does not mean that LEDs are not as good as halogen lamps in terms of penetration. Penetration and color temperature are related to light. When installing car lights, just do not install too white light. If you are still worried, you can install color-changing lights, which are suitable for all-weather use.

Some riders have also mentioned the problem of light attenuation, and this article focuses on this issue.

Everyone knows that the rise of semiconductor materials can be said to be most vivid in the field of LED. Everything inevitably has mixed pros and cons, and the shortcomings of semiconductor materials are obvious. Semiconductor materials that have high requirements on ambient temperature need a stable working environment. This Naturally, LEDs are not immune.

1. Analysis of LED car headlight decay

The undeniable point of LED car headlights is their long lifespan, which can basically reach 30,000 hours, which is several times the lifespan of traditional light sources. There is basically no need to replace lamps. It is also energy-saving, environmentally friendly, non-radiative, and has a relatively fast response. In addition, the volume is relatively small, so the plasticity is relatively high, and the shapes are naturally more diverse.

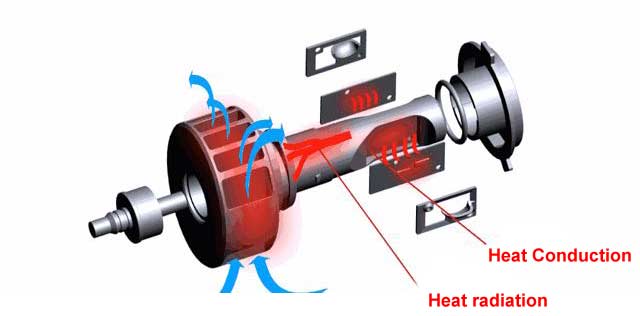

Automobile LED headlights can be said to occupy a mainstream position among current automobile headlights. Such high-power LED energy conversion efficiency is very low. Automotive LEDs usually only convert 10%-25% of the electrical energy into light energy, and the remaining electrical energy is converted into heat energy. The heat generated by traditional halogen lamps is much higher than that of LEDs, but the output brightness of halogen lamps does not change due to heat. Its thermal design mainly focuses on the temperature uniformity design inside the casing. However, the light output of LED will affect the stability of its PN junction temperature due to its own heat or the high temperature from the engine compartment. Important parameters such as LED luminous flux and wavelength are directly affected by the PN junction temperature. This bad temperature cycle will lead to luminous efficiency. and a sharp decline in lifespan. This situation is generally called light decay.

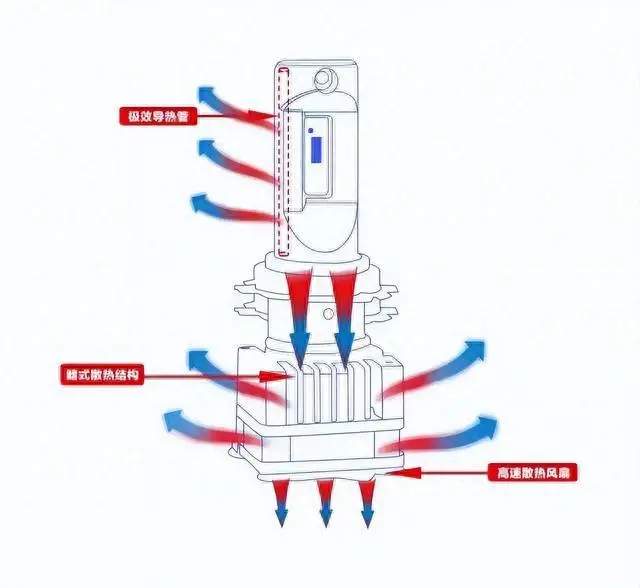

So how to solve the problem of light attenuation caused by high temperature? Two methods, one is the design of thermal channels, and the other is to use materials with better thermal conductivity.

As the name suggests, the design of a hot channel is to design a channel that is more conducive to dissipating heat so that the heat can be quickly discharged or cooled. Basically all vehicles are equipped with a center grille in front of the front. The center grille design actually uses the airflow during the driving process of the vehicle to take away the heat in the engine compartment. It is a relatively reasonable heat channel. Adding a fan to the LED headlight is actually similar to the central grid, but the high-temperature light of the PN junction relies on the fan, and the thermal conductive glue cannot be transmitted to the fan. Among them, the requirements for thermally conductive materials are good, and there is no problem with heat dissipation. It is futile if the heat conduction is not good.

The most direct contact with lamp beads is the substrate and lens. However, the lens obviously has no way to conduct heat. Only by choosing a substrate with better thermal conductivity can the difficult heat dissipation task be completed. Currently, the substrates used by LEDs are generally divided into: aluminum substrates, ceramic substrates and double-sided copper substrates. Which of the three substrates is more suitable for use in automotive LED headlights? You can first look at their respective advantages and disadvantages.

2. Ceramic substrate

Advantages: The thermal conductivity of aluminum substrate is nearly a hundred times higher, it is resistant to high temperatures and has strong mechanical strength.

Disadvantages: The current domestic production capacity is not enough to supply such a huge industrial chain as LED.

3.Aluminum substrate

Advantages: Compared with epoxy resin substrates, metal substrates are significantly more reliable, have better stability, and excellent thermal conductivity.

Disadvantages: An insulation layer needs to be made before it can be put into use, and the overall thermal conductivity is still determined by the insulation layer. The thermal conductivity is about 2-3W/(m·K). Unless thermal and electrical separation is carried out, the whole process is somewhat outweighed by the costs in terms of process costs.

4. Double-sided copper substrate

Advantages: It can achieve efficient heat dissipation and super light concentration, and the thickness in the middle is very close to that of halogen filament; double-sided copper is more superior and has been regarded as the development direction of automotive LED lights in the future. LED headlight copper strip heat dissipation is a passive heat dissipation method. The larger the copper strip heat dissipation area, the better the heat dissipation effect.

Disadvantages: Expensive.

5. Summary

The above contrast is obvious. Whether metal substrates will be replaced by ceramic substrates, double-sided copper substrates are the development direction of LED car lights. They are still one of the best substrates on the market, and the price will naturally not be cheap. When buying LED car lights, riders must pay attention to their ability. In terms of brightness, if it is not a color-changing lamp, try not to buy a color temperature greater than 7000K to avoid insufficient penetration.

popnow is a headlight production factory with a history of 17 years. They produce various types of headlights. High-power headlights are currently more popular and will sell better in the market. D series LED headlights are also very good. We can directly use them to replace the original car xenon bulbs.